The Application And Development Trend Of Shichuang Vacuum Coating Machine (pvd Furnace) In Different Industries

[Summary Description] According to the application requirements of different industries, Strong Metal Technology provides customers with one-stop customized services

PVD is the abbreviation of physical vapor deposition technology (Physical Vapor Deposition), which refers to the use of physical methods to vaporize materials (commonly known as targets or membrane materials) into gaseous molecules, atoms or ions under vacuum conditions, and deposit them on the workpiece Forming a thin film technology with a certain special function.

Target working process

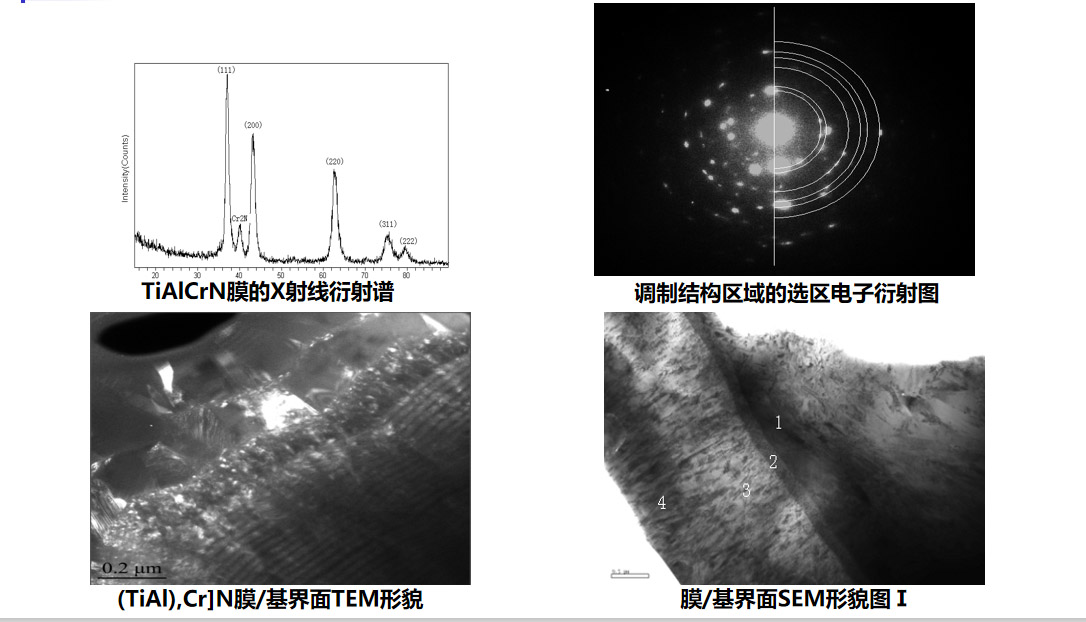

The multifunctional plasma coating equipment developed by Strong Metal with multiple independent intellectual property rights can prepare nano coatings, rare earth modified coatings, super hard coatings and multifunctional composite coatings. A collection of plasma coating equipment that has reached the first-class level in the domestic market can be widely used in surface material treatment, including: hard film coating, thermal barrier coating and decorative coating

Strong Metal provides one-stop solutions, including pre-processing, coating, post-processing, equipment used for quality inspection, production technology and abnormal handling of processed parts, etc.

1. Cutting industry

Can be used for cutting tools and tools to improve the surface performance of the product and increase the lifespan

According to the needs of the development of the manufacturing industry, multi-functional composite tools, high-speed and high-efficiency tools will become the mainstream of tool development. The materials of cutting tools must have high high temperature hardness and wear resistance, necessary bending strength, impact toughness and chemical inertness, and Good manufacturability (cutting, forging, heat treatment, etc.). In order to meet these needs, Shichuang PVD coating machine brings more breakthrough possibilities to the tool industry and greatly improves the performance of the tool.

Cutting tools such as gear hobbing cutters, milling cutters, drills, end mills, etc., after being treated by the composite multi-arc ion plating process, the phenomenon of blade cracks during cutting can be greatly reduced. According to the actual application, the Shichuang PVD coating machine not only improves the cutting conditions, but also increases the service life of the tools to 30%-200%.

2. Mould industry

Provide coating equipment and processes for different types of mold production

In the mold industry, different types of molds have different needs and applications. The ion source system developed by Strong Metal, due to the effect of multi-element co-permeation enhancement, can be targeted to select the following different coating types:

For the need to improve the wear performance of cold-punching dies and prolong its life, C-containing coatings can be used, such as TICN coating

For hot work molds with high processing surface temperature, coatings containing high AI can be used, such as: AICrTiN coating, AITiN coating

The most common form of failure of plastic molds is corrosiveness, and the multilayer CrN coating has been proven to have very good corrosion resistance.

3. Aerospace industry

Strong Metal PVD furnace, Russian technical quality

The coating is used for the characteristics of the aerospace industry and is generally designed to provide thermal barrier function under various load and temperature conditions. Aviation turbine blades are the hottest components of jet engines and are often exposed to extremely harsh environments. Even in the interior of the cold air duct, the blades made of super alloys may still experience extreme failures due to thermal corrosion. In cooperation with scientific research institutes at home and abroad, Shichuang has fully absorbed the mature technology of the originally imported Russian models and successfully prepared a coating machine with thermal barrier coating function by using the independently developed arc ion coating system. The coating has good film-base adhesion, excellent high-temperature oxidation resistance and thermal corrosion resistance, and high utilization rate of alloy targets. It has been successfully applied to major aero-engine companies.

4. Hardware decoration industry

Because professional, so glorious

Shichuang’s intelligent vacuum ion sputtering coating system is an efficient and pollution-free ion coating equipment. It has the advantages of fast deposition speed, high ionization rate, simple equipment operation, and large production volume. It brings various products to the hardware industry. Various beautiful effects, and the film is wear-resistant and does not fade.

In recent years, competition in the domestic decorative board market has continued to intensify. As the main drafting unit of the team standard for "Decorative Stainless Steel Plates", Shichuang has continuously made innovations in stainless steel decorative plate products based on customer needs with a more professional and focused attitude, and successfully filled the blank of the stainless steel decorative plate industry standard.