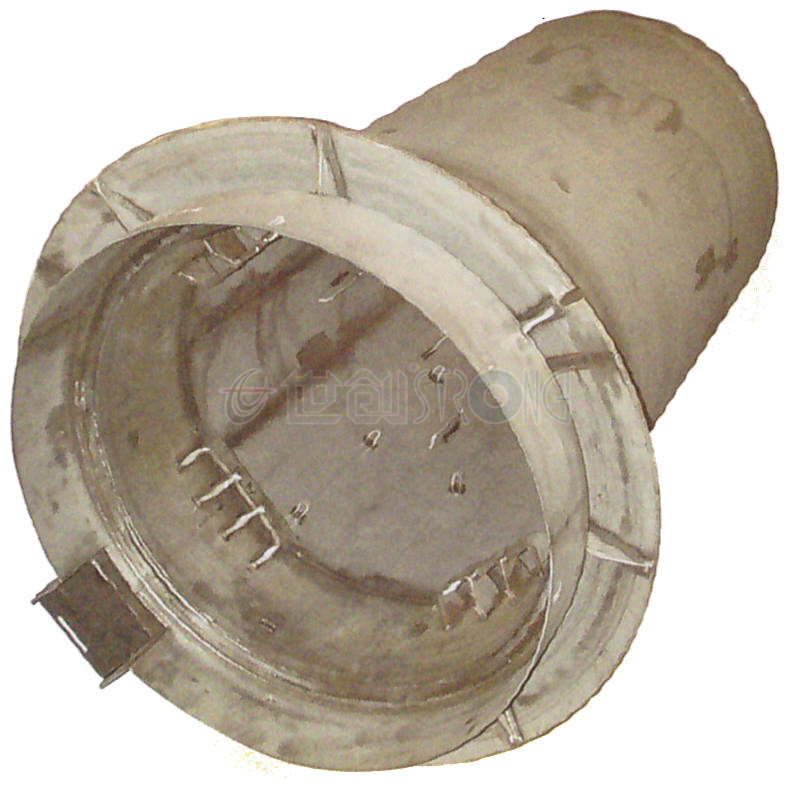

Custom 301s 601 Muffles For Nitriding Furnaces

Brand Strong

Product origin China

Delivery time 30

Supply capacity 500

Long life nitriding muffles with super long service time;

High quality refractory nickle chrome alloy from international brands;

Custom 301s 601 Muffles For Nitriding Furnaces

Long life nitriding muffles with super long service time

High quality refractory nickle chrome alloy from international brands

Custom Made Muffles for Nitriding Furnaces

The muffle is the core component of bright annealing furnaces. Strong muffles feature energy-saving and long service time. Strong Metal has over 30 years experience in designing and manufacturing muffles for industrial furnaces in various application such as horizontal furnaces, vertical furnaces, bell type furnaces, nitriding(nitrocarburizing) furnaces, carburizing(nitricarburizing) furnaces, ammonia decomposing furnace, conveyor furnaces, vacuum furnaces, ect.

Strong Metal's muffle designing engineers have accumulated extensive know-how on manufacturing the right muffle for particular applications over three decades. No matter small or large, simple or complicated, we can make as per your requirement.

Features:

1) High quality materials for muffles from famous international brands such as outokumpu 310s, inconel 601, VDM 601, Nippon Yakin Kogyo ect.;

2) Strong Metal's exclusive muffle design;

3) Custom design, muffle manufacturing limit: length 17.5meters;

4) One years' guarrantee;

Specification:

| Model: | Custom make muffle |

| Name: | imported high temerature Muffle for horizontal furnaces |

| Type: | Atmosphere muffle |

| Heating Method: | Oil, gas, electricity |

| Design | Custom |

| Material options | Outokumpu, inconel, VDM, Yakin, etc... |

| Muffle Thickness: | 6/8mm |

| Muffle Length: | Up to 17.5 meters |

| Temperature: | Up to 1150 C |

| Quality control: | ISO9001 |

| Guarrantee: | 12 months |

| Lead time | 30 days |

| Origin | China |

The production procedure of muffle:

1) Material preparation;2) Cutting;3) Bending;4) Welding;5) Inspection;6) Packaging.

The images of equipment and production: