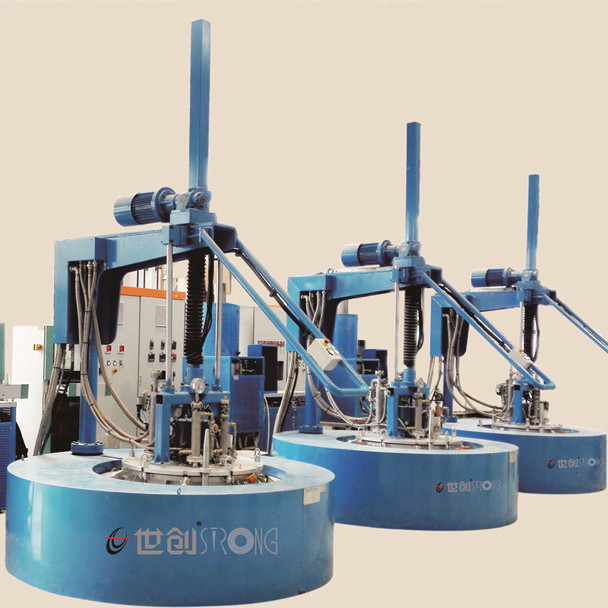

Precision controllable atmosphere vacuum pulse pit type nitriding furnace

Brand SOLO

Product origin CHINA

Delivery time 60

Supply capacity 100

Advantages: Pit furnaces are suitable for long shafts and other workpieces. From simple independent heat treatment furnaces to the most complex fully automated systems, accurate data analysis plays a solid role in the traceability and stability of enterprise products.

Vacuum pulse ion nitriding is a new technology. Compared with traditional ion nitriding, it has many advantages. First, pulse ion nitriding has the characteristics of individual control of physical parameters, independent adjustment of process parameters, and a wide range of changes; because of the pulse power supply to arc discharge The inhibitory effect of, so there is no need to plug holes for many parts, high-quality surfaces can be obtained, and no burns; it can improve the depth of the layer, save energy, and improve the utilization rate of the equipment; it can realize ions in deep holes, narrow slits, and micropores. Nitriding.

Precision controllable atmosphere vacuum pulse well type nitriding furnace

Vacuum pulse ion nitriding is a new technology. Compared with traditional ion nitriding, it has many advantages. First, pulse ion nitriding has the characteristics of individual control of physical parameters, independent adjustment of process parameters, and a wide range of changes; because of the pulse power supply to arc discharge The inhibitory effect of, so there is no need to plug holes for many parts, high-quality surfaces can be obtained, and no burns; it can improve the depth of the layer, save energy, and improve the utilization rate of the equipment; it can realize ions in deep holes, narrow slits, and micropores. Nitriding.

The vacuum pulse ion nitriding process is to pass ammonia gas into the vacuum furnace, that is, after the workpiece is loaded into the vacuum furnace, the mechanical pump starts to evacuate. When the vacuum degree reaches the set value (mostly 1.33Pa), the power is heated up. At the same time, continue to evacuate to maintain the vacuum degree in the furnace. After the furnace temperature reaches the required nitriding temperature, keep it for a certain period of time, then stop vacuuming, and pass dry ammonia gas into the furnace to increase the furnace pressure to 50~70Pa , Keep it for a certain time, then vacuum and keep it for a certain time, and then pass in ammonia gas, and repeat this many times until the infiltration layer meets the requirements. The furnace temperature remains constant throughout the nitriding process.

After vacuum pulse ion nitriding, the surface hardness of the workpiece is higher, and the nitriding speed is much faster than that of ordinary gas nitriding, such as 38CrMoAl steel. Vacuum pulse nitriding at 550℃×10h has similar nitriding compared with ordinary gas nitriding at 540℃×33h. Layer depth.

Advantages: Pit furnaces are suitable for long shafts and other workpieces. From simple independent heat treatment furnaces to the most complex fully automated systems, accurate data analysis plays a solid role in the traceability and stability of enterprise products. Each device is specially customized for you!

Performance: (1) Temperature: 700℃; (2) Material: Furnace: inconel 600

Material: Brand: Shichuang Technology

Specification: SN-404/609/710/1015

Features: Nitriding treatment of carbon steel and stainless steel can be done