Vacuum Furnace For Metal Heat Treatment

Brand STRONG

Product origin CHINA

Delivery time 120

Supply capacity 100

Vacuum quenching and vacuum tempering of tool and die steel; solid solution and annealing of stainless steel and titanium alloy; strengthening treatment of high-speed steel; powder steel sintering; vacuum stress relief annealing of tool and die, etc.

Download

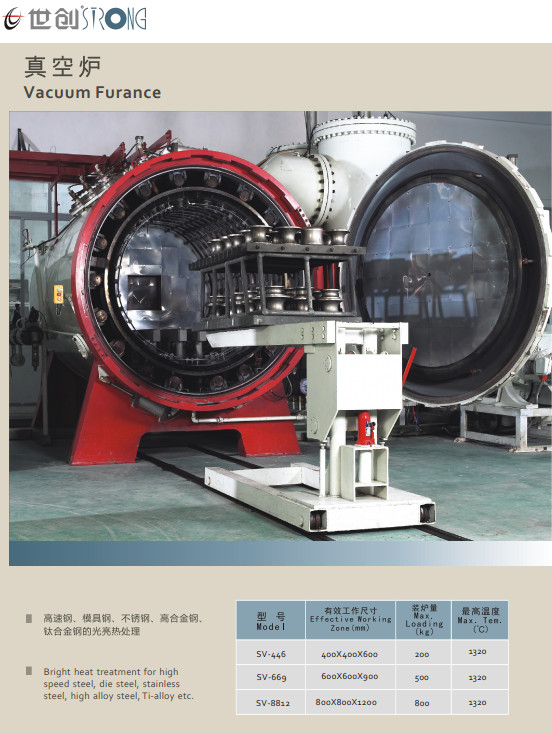

Vaccum Furnace

This furnace is pre-vacuum furnace for heat treating high quality mechanical parts of high speed steel, die steel, stainless steel, high alloy steel, titanium alloy etc..

Comparison of vacuum heat treatment and protective atmosphere heat treatment process:

1.Vacuum heat treatment: no oxidation, no decarburization

2.Protective atmosphere heat treatment: oxidation and decarburization are difficult to control

Vacuum furnace, Annealing vcacuum furnace, bright annealing furnace

Strong Metal Develops various heat treating solutions for different industries. Strong Metal provide other energy solutions including gas, oil and electricity. Strong Metal recommends you to consider your environmental protection process also, any energy conservation, gas purification or resource recycling issues, please consult us. Hope we can help you and join hands together to restore a purified Green Earth!

Vacuum Furnace

application for annealing, hardening, air queching and tempering

Vacuum Furnace

bright heat treatment for high speed steel, die steel, stainless steel, high alloy steel, Ti-alloy etc.

Applications:

Most tool and die steels such as H13, D2, C12MoV, SKD61, SKD11, S-136, high-speed steel, 4Cr13, etc.

Description:

This Vacuum heat treatment furnace has the following advantages:

1. Achieve non-oxidation and non-decarburization heating: Since the molds are heated in a vacuum state, the oxygen partial pressure of the residual gas is extremely low, the surface is not oxidized, decarburized, and does not form any toxic products.

2. Small deformation and uniform hardness: Because vacuum heating mainly relies on heat radiation at high temperature, low-temperature convection is weak, so heating is slow, the temperature difference between the surface and the core of the workpiece is small, the expansion and contraction is more uniform, and the thermal stress caused is small, thereby reducing The final deformation of the workpiece.

3. Improve the plasticity and strength of the workpiece: The solid metal is heat-treated under vacuum, and the surface has degassing effect, thereby improving its plasticity and strength.

Vacuum furnace, Annealing vcacuum furnace, bright annealing furnace

Vacuum heat treatment has the following advantages:

◇ Achieve non-oxidation and non-decarburization heating: Since the mold is heated in a vacuum state, the oxygen partial pressure of the residual gas is extremely low, the surface is not oxidized, decarburized, and does not form any toxic products.

◇ Small deformation and uniform hardness: Because vacuum heating mainly relies on heat radiation at high temperature, low temperature convection is weak, so heating is slow, the temperature difference between the surface and the core of the workpiece is small, the expansion and contraction is more uniform, and the thermal stress caused is small, thereby reducing The final deformation of the workpiece.

◇ Improve the plasticity and strength of the workpiece: The solid metal is heat-treated under vacuum, and the surface has degassing effect, thereby improving its plasticity and strength.

◇ Clean the surface of the workpiece: The grease attached to these objects in vacuum belongs to the common aliphatic group, which is carbon, hydrogen, oxygen compounds, and has a high vapor pressure. It is volatilized or decomposed when heated in a vacuum, and then is pumped off by the vacuum pump to make the surface of the workpiece Purification.

Application scope:

Most tool and die steels such as H13, D2, C12MoV, SKD61, SKD11, S-136, high-speed steel, 4Cr13, etc.

Suitable process:

Vacuum quenching and vacuum tempering of tool and die steel; solid solution and annealing of stainless steel and titanium alloy; strengthening treatment of high-speed steel; powder steel sintering; vacuum stress relief annealing of tool and die.

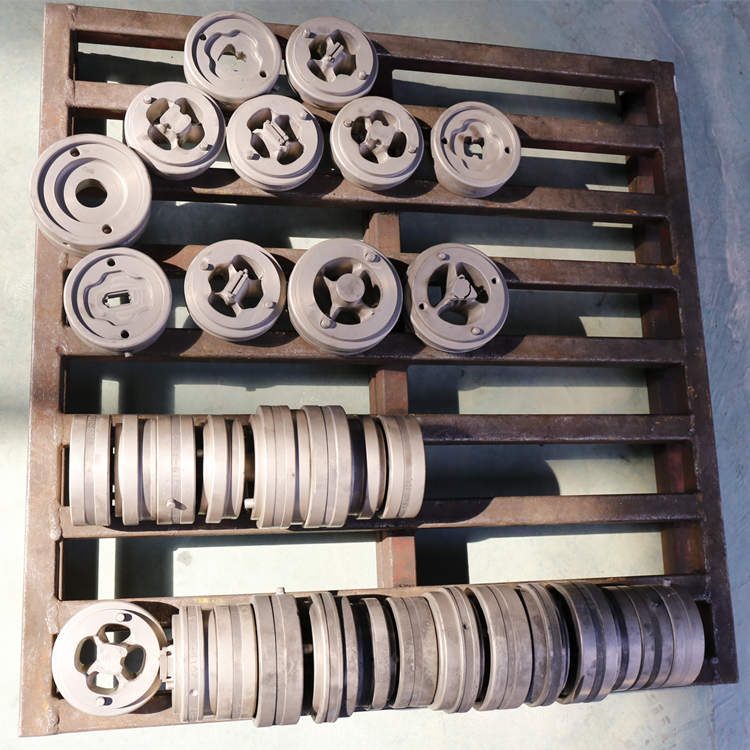

typical application:

Die-casting molds, cold punching molds, extrusion molds, feed molds, plastic molds, tools and other types of molds.

Scope of application:

Vacuum quenching: suitable for hot work and cold work die steels with high hardenability.

Vacuum oil quenching: suitable for all kinds of hot work and cold work die steel.

Comparison of vacuum heat treatment and protective atmosphere heat treatment process

Vacuum heat treatment: no oxidation, no decarburization

Protective atmosphere heat treatment: oxidation and decarburization are difficult to control

A brief introduction of Strong Metal

Guangdong Strong Metal Technology Co., Ltd.(StrongMetal) is public listed high tech company which is committed to develop and manufacture advanced heat treating equipment and provide customized heat treatment engineering for various industries including aerospace, steel, machinery, tool, automobile, electronics, home appliaces, contruction, ect.

Guangdong Strong Metal Technology Co., Ltd.(StrongMetal) is public listed high tech company which is committed to develop and manufacture advanced heat treating equipment and provide customized heat treatment engineering for various industries including aerospace, steel, machinery, tool, automobile, electronics, home appliaces, contruction, ect.

Strong Metal Expertise covers comprehesive heat treatment processes such annealing, hardening, normalizing, tempering, carburizing, nitriding, carbonitriding, nitrocarburizing, ion plating ...

Strong Metal Equipment Manufacturing includes: Continuous vertical bright annealing line(BAL) for stainless steel strips;Continuous horinzontal bright annealing line(BAL) for stainless steel strips;Continuous pickling and annealing line(PAL) for steel strips;Mesh belt conveyor furnace for heat treating metal parts;Intelligent flexible heat treatment center;Horizontal hardening and tempering line;Bell-type furnace line;Bell-type nitridding furnace;Pit type carburizing furnace; Pit type vacuum impulse nitriding furnace;Bell-type vacuum cleaner..

Our advantages

Experience

Strong Metal has over 30 years’experience in heat treatment and has accumilated abundant know-how techniques which bring values to our customers.

Innovation

Strong Metal keeps continuous cooperation with high level universities and global companies for R&D on heat treatment technology which keep our customers’businesses forward-looking and competitive

Quality

Strong Metal ISO9001 quality management system employs strict control on equipment and materials provided by strong metal.

Team

Strong Metal is multi-disciplined team engaging in within 24 hours responsive global services for heat treatment equipment design, manufacturing, engineering, erection, commission, training.

Who we serve

Strong Metal provides various heating solutions for industries including steel industry, machinery, aerospace, automobile, arms, tool, home appliances, building, electronics, electrical.

Strong Metal enjoys great honor for serving customers some of which are the leaders in their industries, just name a few below:

Vacuum furnace, Annealing vcacuum furnace, bright annealing furnace