- Muffles for Furnaces

- Muffles For Horizontal Furnaces

- Muffles For Vertical Furnaces

- Muffles For Bell Furnaces

- Muffles For Carburizing Nitriding

- Muffles for conveyor furnaces

- Muffles For Ammonia Crackers

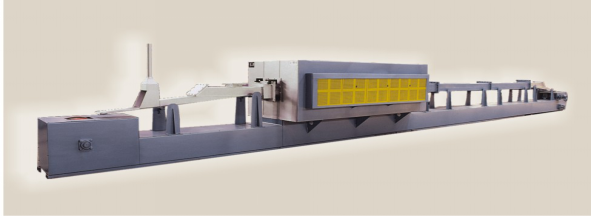

Innovative Conveyor Belt Furnace Unveiled

With the industry development, more and more manufacturers are now pursuing more efficient and low- energy consumption solution for the solution annealing treatment of stainless steel pipes, pipe fittings, and daily stainless steel products. The Conveyor Belt Furnace is the main product in the Strongmetal. As the main product in our company, we continue to convey high- effeciency and less- consumption Conveyor Belt Furnace. We promise that we will try our best to satisfact your requestions.

Why the high- effeciency and less- consumption Conveyor Belt Furnace popular?

Continuous Production Capability

Enables 24/7 uninterrupted operation, maximizing output while minimizing startup/shutdown energy losses. The conveyor belt transports materials continuously through the furnace, eliminating batch processing delays.

Superior Energy Efficiency

Designed with insulated chambers and optimized heat circulation systems (e.g., recirculating fans), reducing heat loss and ensuring uniform temperature distribution. Some models integrate waste heat recovery systems to reuse thermal energy.

Low Maintenance & Operational Costs

Simple mechanical structure (e.g., durable conveyor belts with minimal moving parts) lowers maintenance needs. Long service life and reduced downtime contribute to cost-effectiveness.

Uniform Heating & Quality Consistency

Material move steadily through the furnace, ensuring consistent exposure to heat. This reduces rework/defects, imporoving yield and minimizing resource waste.

Space Optimization & Scalability

Horizontal conveyor design occupies less floor space compared to batch furnaces. Modular systems allow easy expansion of production lines to meet growing demands.

Environmental Compliance

Lower energy consumption translates to reduced carbon emissions, aligning with global sustainability standards and minimizing environmental impact.

What about the Conveyor Belt Furnace applications?

It is widely used in metal bright heat treatment, powder metallurgy sintering, and metallic material brazing for various precision magnetic materials, stainless steel, pipes, electronic components, hardware products, etc. It is also applicable for bright demagnetization of magnetic materials.

What about the detail of the Conveyor Belt Furnace?

General Description of Installation

Type: Horizontal continuous

Heating mode: Electric

Protective Gas: Ammonia decomposition gas ( 75% H2 + 25% N2)

Overview of Prpduction Line Parameters

Total power : ~300kw(without ammonia decomposing generator)

Width of SS belt : 600mm

Production : Max. 500kg/h

Equipment Dimensions

Loading length : 4500mm

Heating furnace length : 8000mm

Water jacket length : ~16000mm

Unloading length : ~4000mm

The Strong Metal's Conveyor Belt Furnace is set to disrupt the heat treatment industry with its advanced features, high-performance capabilities, and unwavering reliability. It is expected to become the go-to choice for manufacturers seeking to enhance their heat treatment processes and gain a competitive edge in the market.

Service Hotline | +8615820281234

E-mail | mac@strongmetal.com.cn

Website | www.strong-furnace.com

Address | No. 32, Shizhou, Chencun, Shunde, Foshan, Guangdong