Brush roll adjustment of degreasing cleaning line

Hello everyone, today mori briefly introduces the method of adjusting and controlling the brush roller of degreasing cleaning.

1. Speed control:

The speed of the brush roller can be controlled by adjusting the speed of the motor, which is suitable for occasions where the speed of the brush roller is precisely controlled

2. Pressure control:

The pressure of the brush roll can be controlled by adjusting the air pressure or hydraulic pressure of the pressure system, which is suitable for brush roll operation where stable pressure is required.

3. Direction control:

The brush set can change its direction through a steering mechanism and can be used to clean or paint surfaces with special shapes such as bevels or curved surfaces.

4. Cleaning control:

The brush roller will accumulate dirt in the process of use, and it needs to be cleaned regularly. The cleaning effect can be controlled by controlling the supply of cleaning agent and cleaning time

5. Position control:

The position of the brush roll can be controlled by motor or cylinder and is suitable for fields where the brush roll needs to be positioned

6. Temperature control:

Some brush rollers need to work within a certain temperature range, which can be controlled by heating or cooling

System to control the temperature of the brush roll

Finally, if it is not a professional and technical personnel, it is not recommended to adjust the brush roller at will to avoid many uncertainties!

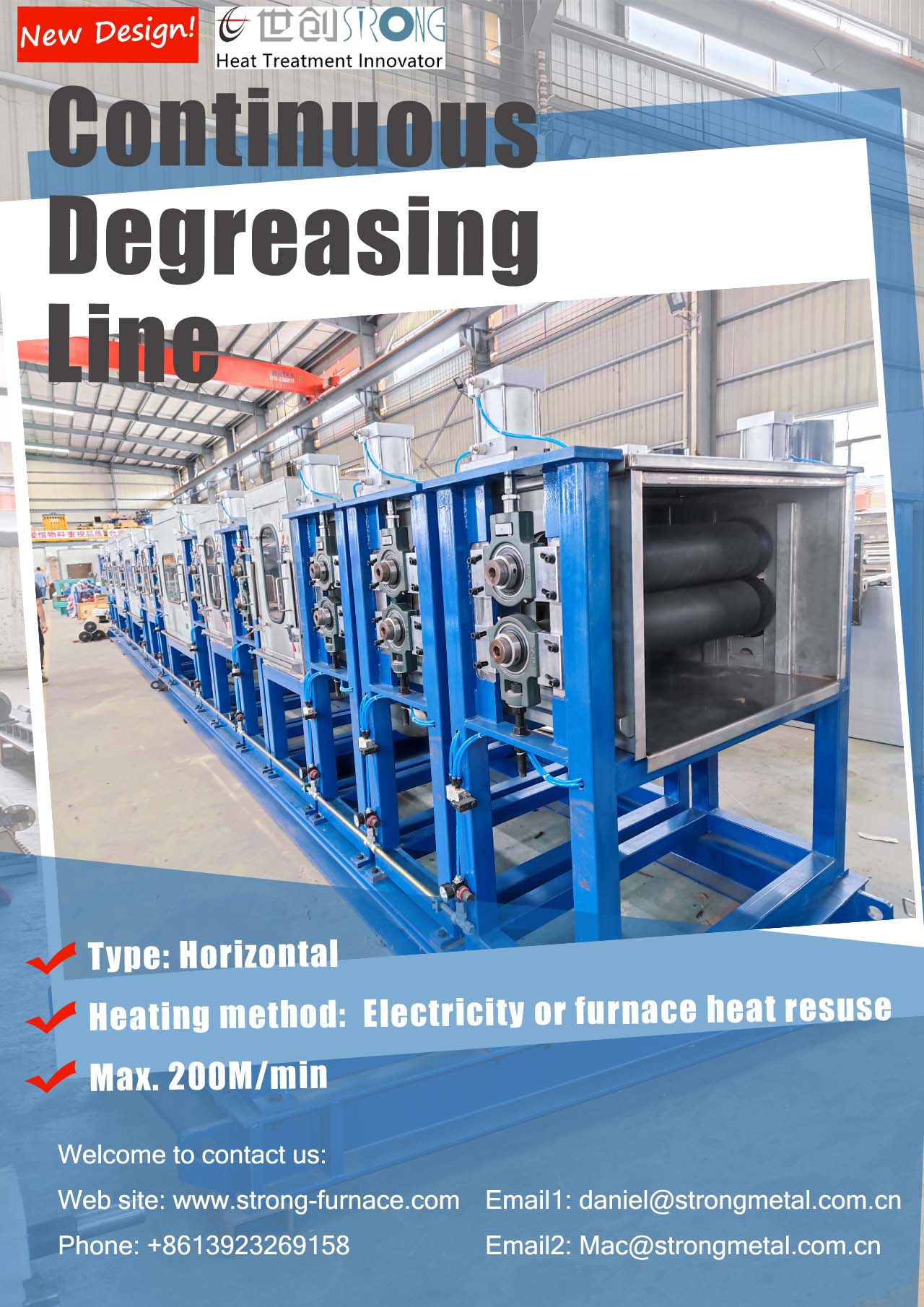

Daily introduction——Degreasing Line

A degreasing line is a system of tanks, pumps, and conveyors used to remove grease, oil, and other contaminants from metal parts. The parts are typically dipped in a heated alkaline solution, which breaks down the grease and oil. The parts are then rinsed in clean water and dried.

Degreasing lines are used in a variety of industries, including:

Metalworking

Machining

Automotive

Aerospace

Electrical

Electronics

The specific components of a degreasing line will vary depending on the size and complexity of the parts being cleaned, as well as the type of contaminants being removed. However, most degreasing lines will include the following:

Tanks: The tanks are where the parts are immersed in the cleaning solution. They are typically made of stainless steel or other corrosion-resistant materials.

Pumps: The pumps circulate the cleaning solution through the tanks.

Conveyors: The conveyors move the parts through the degreasing line.

Heating system: The heating system keeps the cleaning solution at a constant temperature.

Filtration system: The filtration system removes contaminants from the cleaning solution.

Degreasing lines can be either manual or automated. Manual degreasing lines require operators to manually load and unload the parts, as well as monitor the cleaning process. Automated degreasing lines are more efficient, but they can be more expensive.

The frequency with which parts need to be degreased will depend on the type of contaminants being removed, as well as the operating environment. In general, parts should be degreased as soon as possible after they become contaminated.

Degreasing lines are an important part of many manufacturing processes. They help to ensure that parts are clean and free of contaminants, which can improve the quality of the finished product and prevent problems such as corrosion and rust.

Here are some of the benefits of using a degreasing line:

Improves the quality of the finished product

Prevents corrosion and rust

Reduces the risk of fire

Improves the efficiency of the manufacturing process

Saves time and money

If you are looking for a way to improve the quality of your manufactured products, a degreasing line is a good option to consider.