- Muffles for Furnaces

- Muffles For Horizontal Furnaces

- Muffles For Vertical Furnaces

- Muffles For Bell Furnaces

- Muffles For Carburizing Nitriding

- Muffles for conveyor furnaces

- Muffles For Ammonia Crackers

What are the advantages and problems of continuous annealing compared to bell type annealing?

Bell type annealing can be divided into single stack annealing and multi stack annealing. According to the different forms of sheet and coil, there are two types of annealing: tight coil annealing and loose coil annealing (see Bell type annealing). Most bell type furnace annealing, although with a long processing cycle, is more commonly used in the annealing of cold-rolled steel sheets and strips due to the large number of furnaces, flexible use, and low investment. In the late 1970s, strong convection all hydrogen bell type furnace annealing (HICON/H2) emerged. Using pure hydrogen gas as the protective gas, the large blade centrifugal vortex machine generates strong convection, which increases the heating and cooling speed of the plate by 40% to 50%; Shortened annealing cycle and low energy consumption; We can obtain high-quality surfaces that are close to what continuous annealing can achieve.

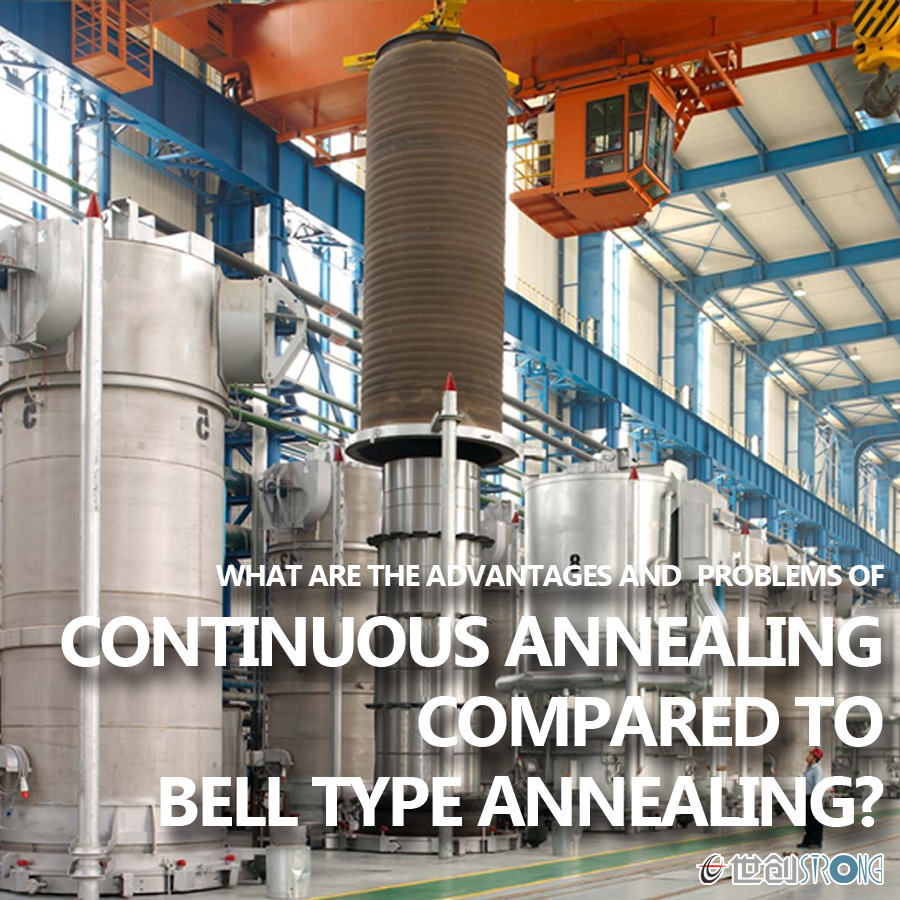

Continuous annealing: Vertical continuous annealing and horizontal continuous annealing. Protective gas is generally introduced into the furnace. Continuous annealing is a new annealing technology for cold-rolled steel sheets and strips introduced in the 1970s, with a large annealing yield. After years of development, continuous annealing equipment has been continuously improved and gradually specialized according to the variety of production, in order to reduce the cost of unit infrastructure and improve product quality. Continuous furnace annealing can not only produce special deep drawing grade strip steel with good surface grade, but also produce high-strength plates through continuous annealing.

(Vertical Continuous Annealing Line)

What are the advantages and problems of continuous annealing compared to bell type annealing?

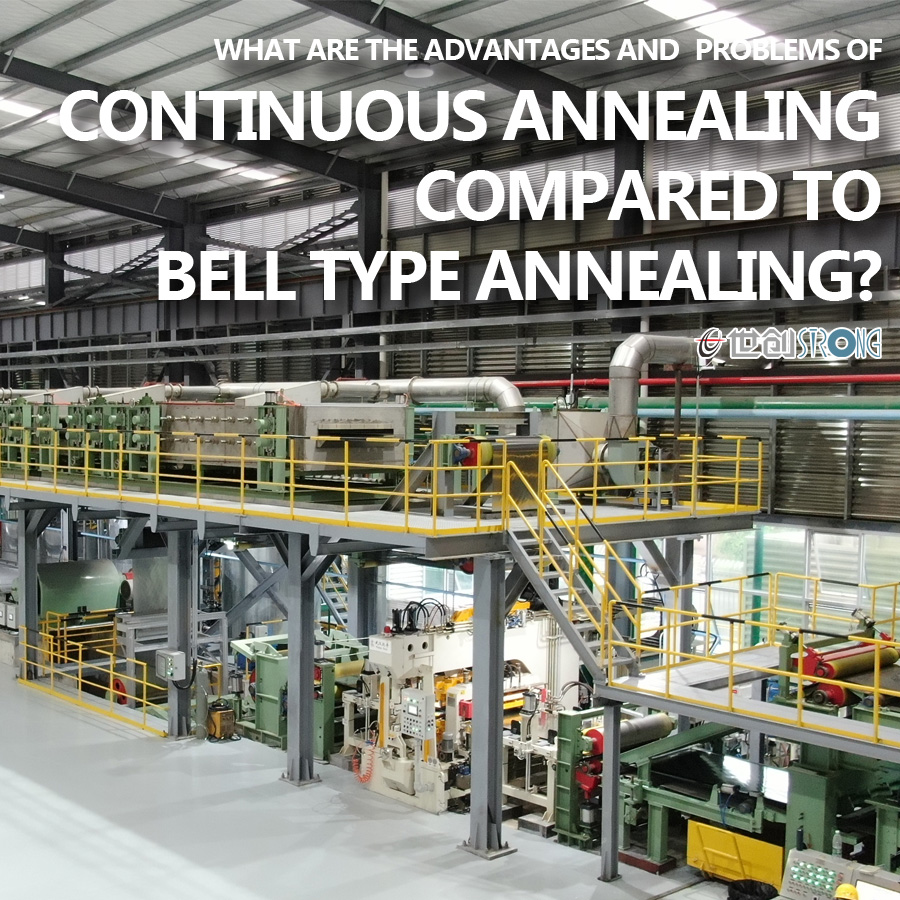

Continuous annealing can produce both soft steel plates and high-grade high-strength steel plates. The advantages of product development are obvious, such as continuous production, short production cycle, good plate shape, and smooth product surface. However, the investment is large and the technology is too complex, making it more suitable for large-scale and few variety production. This annealing process is increasingly popular in large cold rolling plants. Compared with continuous annealing, bell type annealing has advantages in producing soft steel plates, flexible production, and low construction investment. However, it has some shortcomings in high-strength steel plate production, such as intermittent production, long production cycle, and low efficiency. It is suitable for small batch and multi variety production. This annealing process is very popular in private cold rolling plants or small cold rolling plants.

(Horizontal Continuous Annealing Line)

Compared with bell type annealing, the advantages and problems of continuous annealing are briefly described as follows:

1) The advantages of continuous annealing

(1) The product has good quality, a flat shape, clean surface, and uniform performance.

(2) High yield, without defects such as bonding and folding that are prone to occur during bell type annealing.

(3) Diversified variety, in addition to producing all types of hood shaped annealing furnaces, it can also produce high-strength boards, electrical boards, etc.

(4) Compact layout with small footprint.

(5) Short production cycle and fast delivery.

(6) Energy saving of over 20%, labor saving, and low production costs.

2) The drawbacks of continuous annealing

(1) The coverage range of the specification range should not be too wide.

(2) The flexibility of product changes is slightly poor. When the output changes in the year, the opening and stopping of the bell type annealing furnace are very flexible, making it difficult to achieve continuous annealing furnaces.

Despite the rapid development of continuous annealing production, it is currently unable to completely replace the bell type annealing furnace. For a considerable period of time in the future, both full hydrogen bell type annealing and continuous annealing will coexist, and the advantages of the two annealing processes will complement each other.