- Muffles for Furnaces

- Muffles For Horizontal Furnaces

- Muffles For Vertical Furnaces

- Muffles For Bell Furnaces

- Muffles For Carburizing Nitriding

- Muffles for conveyor furnaces

- Muffles For Ammonia Crackers

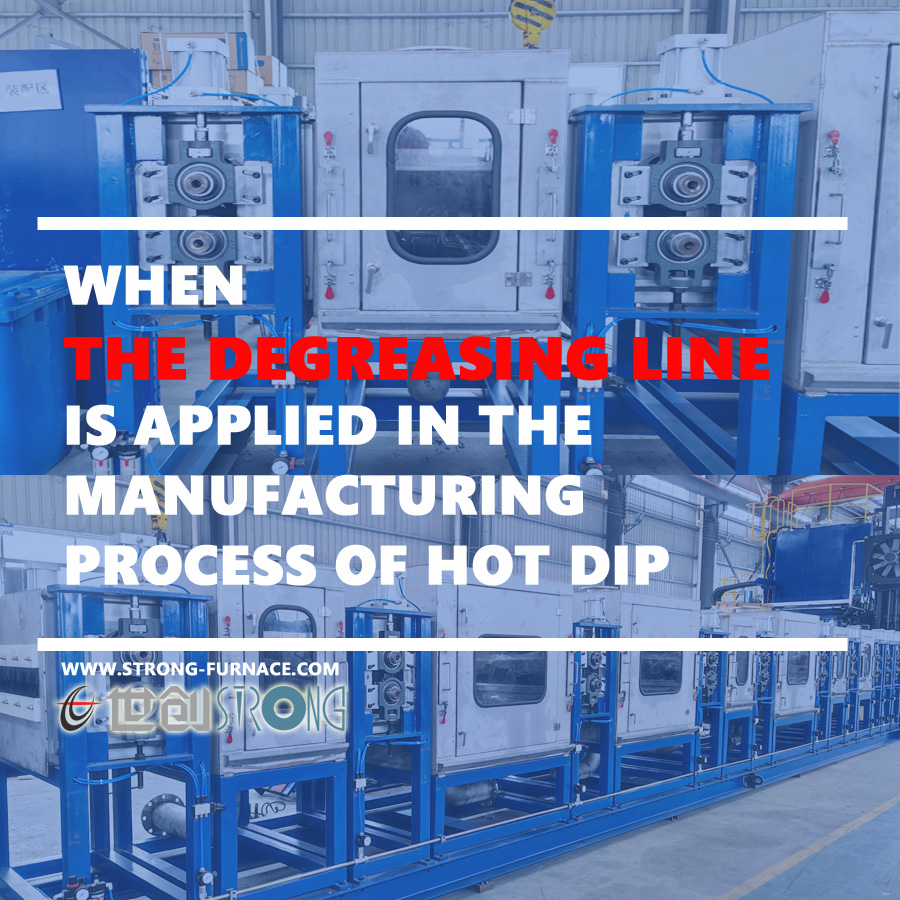

When the degreasing line is applied in the manufacturing process of hot dip galvanized coil

The manufacturing process of hot-dip galvanized coil is a complex and delicate process that includes the following three main steps:

1. Steel plate surface pretreatment: This is the first step in the entire manufacturing process. At this stage, the surface of the steel plate needs to go through a series of treatments, including pickling, oil removal, rust removal, water washing, etc. The purpose of these treatments is to ensure that the surface of the steel plate is clean and smooth, thus ensuring that a uniform and continuous alloy layer can be formed during the subsequent hot dip galvanizing process. The fine operation and technical requirements of these processing steps directly affect the quality of hot-dip galvanized coil.

2. Hot dip galvanizing: The steel plate after surface pretreatment will enter the hot dip galvanizing step. In this step, the treated steel plate is soaked in high-temperature liquid zinc. The goal of this process is for the zinc to chemically react with the surface of the steel plate to form an alloy layer. This alloy layer is the main structure of the hot dip galvanized layer, which has excellent corrosion resistance and can protect the steel plate from the external environment.

3. Post-treatment: After hot dip galvanizing, the steel plate needs to go through a series of post-treatment steps, including cooling, stretching, shearing, etc. The goal of these post-treatment steps is to further enhance the performance of the hot dip galvanized layer and make it meet specific product requirements. For example, the cooling process can make the alloy layer more stable, and the stretching and shearing process is to adjust the steel plate to the desired shape and size. These steps also require a high degree of technical manipulation and fine process control.

In general, the manufacturing process of hot-dip galvanized coil is a complex and delicate process, each step requires a high degree of technical operation and fine process control to ensure the quality and performance of the final product.

STRONG METAL has customized an efficient degreasing line for its customers:

(Indian customers visit degreasing machines made by STRONG METAL)

New Design Continuous Degreasing Line

Application:

The degreasing line is for cleaning with a cleaning agent to remove the residue and the water is squeezed out and dried to ensure that the steel strip is clean before entering the annealing furnace;

Product Descrption:

1) online/offline

2) with driving terminal

3) PLC control system

4) degreasing section, water cleaning section and drying section

Specification:

Type: Horizontal

Heating method: Electricity or furnace heat resuse

Max. output: 300MT/day

Images of the line: