- Muffles for Furnaces

- Muffles For Horizontal Furnaces

- Muffles For Vertical Furnaces

- Muffles For Bell Furnaces

- Muffles For Carburizing Nitriding

- Muffles for conveyor furnaces

- Muffles For Ammonia Crackers

Heat treatment of cold worked stainless steel strip

continuous bright annealing line for heat treatment of stainless steel strip

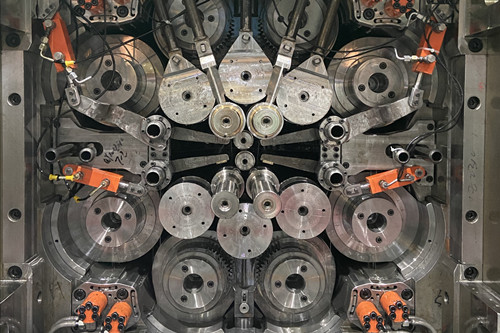

Stainless steel cold work -20hi rolling mill

Heat treatment and cold work forming are generally used to improve the microstructure of steels in order to achieve the desired mechanical properties, which is why it is important to know what treatment to use according to the type of steel, for example, the heat treatment for austenitic stainless steel.

The importance of knowing what is the best treatment also lies on the fact that some undesired side effects may arise when using the wrong treatment or the wrong conditions to perform it.

Regarding the heat treatment for austenitic stainless steel, it is important to highlight that annealing during forming operations is one of the most common processes. This process helps relieving stress from the forming operations, thus helping improve the mechanical properties of the material.

On the other side, it is important to consider that, while martensitic steels are hardened by heat treatment, austenitic stainless steels (300 series) cannot be hardened this way because they do not experience phase changes during heating or cooling.

In addition, regular heat treatment may alter a the austenitic stainless steel main properties, such as being non-magnetic, high resistance to corrosion, good permeability and weldability, excellent toughness, low ties stress and relatively high tensile strength, and of course, a very considerable durability.

So, the question “how to proceed with the heat treatment for austenitic stainless steel?” arises.

Normally, cold worked austenitic stainless steels contain martensite as a result from the strain induced during forming operations. This martensite may reduce the corrosion resistance of the steel, creating the possibility of having stress corrosion cracking.

In general, the microstructure of cold worked austenitic stainless steels experiences many changes, evolving through precipitation, recovery, recrystallization and grain growth. In order to control this phenomenon, a special approach is needed.

Some of the recommendations to relieve stress, retransform martensite back to austenite and provide low magnetic permeability through heat treatment for austenitic stainless steel include:

Slow controlled cooling in order to avoid distortion issues and residual thermal tensile stress.

Controlled temperature ranges in order to avoid making the steel sensitive to corrosion and to avoid precipitates.

The temperature range between 480-900 Celsius degrees should be avoided.

Furthermore, each grade of the stainless steel should be treated with a specific stress relieving treatment and a specific temperature range after being cold formed or after going through machining operations. Some of this treatments are coded and described by the British Stainless Steel Association as follows:

A: a treatment with temperatures between 1050-1120 Celsius degrees with slow cooling.

B: temperature of 900 Celsius degrees with slow cooling.

C: temperature range between 1050-1120 Celsius degrees with fast cooling.

D: specially used to achieve dimensional stability, with temperatures ranging from 210 to 475 Celsius degrees with slow cooling taking approximately 4 hours for each 25 mm of section.

In conclusion, the heat treatment for austenitic stainless steel is a complex process, which should be performed under very controlled conditions and with a good knowledge of what needs to be done to achieve the desired results. If you are looking for high quality austenitic stainless steels, make sure you can count on experts in the manufacturing process and heat treatment for austenitic stainless steel.