Main defects of bright annealed strips

Bonding, oxidation color and performance failure are the three major problems in the annealing process of cold rolled sheet, especially the two defects of bonding and oxidation color are more prominent.

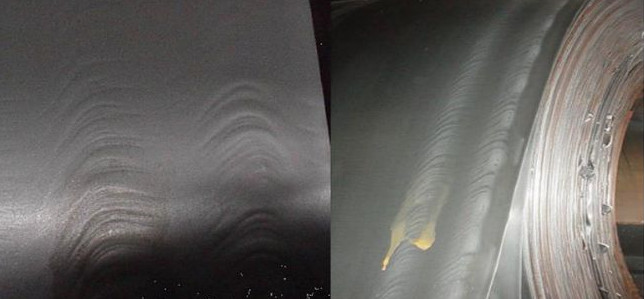

bonding

The tension is too large. Tension is one of the main causes of steel coil bonding. The tension includes the rolling tension and the take-up tension of the rolling mill. When the tension is too large, the gas flow of the shielding gas is not well circulated to cause thermal blockage, and the steel sheet is bonded.

poor shape, the shape of the plate will cause the strip to appear thick on both sides in the longitudinal direction, thin in the middle or thin on both sides, thick in the middle or side waves, middle waves, multiple waves and periodic local waves, etc., high temperature annealing After that, it can produce a bond.

When the coiling occurs, there is a jagged overflow edge, and the coil is not wound up, especially the thinner plate, which is easy to cause bonding.

The emulsion is not pure. There is a foreign matter in the emulsion, which is left between the steel plate and the steel plate after being annealed and evaporated. If it is not cleaned, it will also bond.

over temperature. If there is severe overheating in the furnace, it will inevitably cause bonding. The main reason is that the temperature measuring thermocouple is out of control.

Poor circulation of protective gas in the furnace. Because the stacking of the furnace does not meet the requirements, the shielding gas is not well circulated in the furnace, the furnace temperature is not uniform, the thermal blockage of the individual parts is severe, and the temperature difference is large and the bonding occurs.

The convection plate is deformed, the surface flatness and the smoothness of the surface are affected, and the gas circulation at the edge of the steel coil is affected to form a bond.

stacking too heavy. Mainly refers to the very thin plate, if there is too much pressure, it is likely to bring the bond.

The annealing parameters are not properly selected. Different annealing process parameters should be adopted for steel coils of different specifications and steel grades.

Oxidation colour

The system is not closed.

The protective cover “bulk belly”, crack and flange deformation.

The seal ring is aging and damaged.

The cooler is broken.

high temperature is released. If it is not produced according to the process requirements, the high temperature is released when the production is grabbed, and the steel coil is also oxidized.

The temperature control system is faulty. Whether it is measurement, transmission, or recording, as long as there is a problem in one link, the temperature recorded by the annealing curve will not be accurate, which is also an important factor in oxidation.

The protective gas is not sufficiently purged, and the air in the inner cover and the external quick cooling system is not cleaned. In addition, if it is a steel coil with excessive residual emulsion or high humidity, the purge time should be more than normal, otherwise it will not reach the bright annealing.

At the beginning of the rapid cooling of the spray, the volume of the shunting protective gas is suddenly reduced due to the cooling, and the pressure difference in the furnace causes the negative pressure of the inner cover, which causes air intrusion.

The protective gas has a high dew point. The high dew point indicates that the water content in the shielding gas is high, which will inevitably bring oxidized color to the annealed steel coil.

There are other faults, such as the failure of the pressing device, the failure of the solenoid valve, the failure of the outlet valve, the failure of the circulating fan, and the reasons for the power failure, water stop, and protection of the gas, all of which are factors affecting the oxidation color of the annealed steel coil. .

Performance failure

There is an error in the process system.

the furnace is not correct. When the steel coil is annealed, if the inner diameters are not aligned and the pressure is wrong with each other, the circulation of the shielding gas is not smooth, and the temperature difference in the furnace is large, and the small air volume of the circulating fan may cause some performance mismatch.

under temperature, owed time. If the rated annealing temperature is not reached, the heating is over, and the performance mismatch is prone to occur, which is mainly caused by the failure of the metering equipment. If the heating time is not reached or the holding time is too short, the heating is over, and it is also easy to affect the performance.

---------End----------

Guangdong Strong Metal Technology Co., Ltd. is a professional producer of bright annealing furnaces for hot and cold rolled stainless steel coils, strips, foils.

StrongMetal's Continous bright annealing furnace for 200/300/400 cold rolled stainless steel coils

Max annual throughput: 100k tons

Thickness: 0.25-1.2mm

Width: 800-1350mm

Engergy: LNG

TV: 17