Strongmetal Strives for Excellence, Reignites Pioneering Spirit

Guangdong Strong Metal Technology Co., Ltd. (Abbreviation: Shichuang Technology) is a national high-tech enterprise. It was selected into the list of "Little Giant" enterprises under the "Specialized, Refined, Differential and Innovative" program of the Ministry of Industry and Information Technology in July 2021, recognized as one of the "Top 100 Enterprises for High-Quality Development of Manufacturing Industry in Foshan City" in 2022, and identified as a national industrial machine tool enterprise in 2023.

Also, Annealing heat treatment line and Bell-type Furnace have always been the flagship products of Guangdong Strong Metal Technology Co., Ltd. In the first half of 2025, our company successfully increased the annual sales of our flagship products to over 300 million yuan, and their pre-sales, sales, and after-sales services have received unanimous praise from purchasing customers. Strongmetal will focus on improving the performance and quality of the Annealing heat treatment line and Bell-type Furnace flagship products, and creating high-quality products and services from multiple perspectives.

A.3rd INTERNATIONAL METALLURGICAL TRADEFAIR ANO FORUM FOR SOUTHEAST ASIA

METEC Southeast Asia&GIFA Southeast Asia 2025 is a highly influential professional exhibition for the metallurgical and casting industry in Southeast Asia. It is hosted by the globally renowned exhibition organization Messe D ü sseldorf and will be held from September 17th to 19th, 2025 at the Bangkok International Convention and Exhibition Center (BITEC) in Thailand. As the Southeast Asian series exhibition of the two top global metal industry exhibitions, METEC (Metallurgical Exhibition) and GIFA (Foundry Exhibition) in Germany, this exhibition continues the core positioning of "technological innovation+market docking" and is an important window for enterprises to deeply cultivate the Southeast Asian metallurgical casting market.

B.Scope Of Exhibits: Covering The Entire Metallurgical And Casting Industry Chain

The exhibition sets up two core exhibition areas, "Metallurgy" and "Casting", with exhibits covering the entire industry chain from raw materials, production equipment to testing technology, meeting the display and procurement needs of different enterprises

1. Metallurgical sector

-Metallurgical equipment: smelting equipment, continuous casting and rolling equipment, forging and forging equipment, heat treatment equipment, electronic control testing instruments, etc;

-Metallurgical products: pig iron, sponge iron, black alloy, metal sheet/pipe/profile, annealing heat treatment, bell-type furnace lineferroalloy products, etc;

-Auxiliary materials: carbon materials, refractory materials, metal anti-corrosion coatings, metallurgical chemicals, etc;

-Supporting technologies: energy-saving and emission reduction equipment, automation process control technology, mining and metallurgical equipment, etc.

2. Casting Plate

-Casting equipment: die-casting machines, melting equipment, sand processing equipment, molding and core making equipment, 3D printing additive manufacturing equipment, etc;

-Casting materials: raw and auxiliary materials such as casting resin, quartz sand, bentonite, spheroidizing agent, inoculant, release agent, etc;

-Detection and control: direct reading spectrometer, molding sand performance tester, coordinate measuring instrument, non-destructive testing equipment, etc;

-Casting products: cast steel, cast iron, non-ferrous alloy castings, as well as precision spare parts for industries such as automobiles and ships.

C.The Annealing heat treatment And Bell-type Furnace Exhibition

At this exhibition, Strong Metal Technology Co., Ltd. launched its flagship products, the annealing heat treatment line and the hood furnace, in the spirit of originality, to attract potential customers with the main products. With the on-site explanation of the engineers, Strong Metal Technology Co., Ltd. attracted more overseas customers to enter the Strong heat treatment industry market.

D.Continuous Bright Annealing Production Line For Stainless Steel Strip

Product Overview

Usage: Used for continuous bright annealing of stainless steel strips, general steel, alloy steel, spring steel, copper materials, etc.

Product Details

Usage: Used for continuous bright annealing of stainless steel strips, general steel, alloy steel, spring steel, copper materials, etc.

Belt thickness: 0.1~3mm

Bandwidth: 250~1450mm

Natural gas (LNG), liquefied petroleum gas (LPG), and diesel can be chosen as the main heating methods for the furnace body.

The unit of the stainless steel strip bright annealing production line consists of an inlet section, an inlet loop, a degreasing section, a process section, an outlet loop, and an outlet section.

By adopting automated control, a highly integrated and precision controlled production line has been formed, achieving technological integration and innovation in the continuous production line of stainless steel cold-rolled strip.

Features: Fast heating speed, low energy consumption, low cost, safe and reliable, high degree of automation, customizable.

Application scope: Widely used in metallurgy, special steel, and precision strip industries.

E. Bell-type Furnace

Product Overview

The hood type vertical furnace liner is suitable for continuous bright annealing of ordinary carbon steel, alloy steel, spring steel, copper strip, etc.

Product Details

Our company can design and manufacture muffle tank sizes, as well as various types of hood type bright annealing furnace liners for high, medium, and low temperatures according to user requirements.

The hood type vertical furnace liner is suitable for continuous bright annealing of ordinary carbon steel, alloy steel, spring steel, copper strip, etc.

Maximum loading capacity: 24000kg

Maximum loading diameter: 1400mm

Maximum loading height: 2900mm

D.Exhibition Value And Significance

As a leading exhibition in the Southeast Asian metallurgical casting industry, the core values of this exhibition are reflected in three aspects:

1. Market expansion advantages: The manufacturing industry in Thailand and Southeast Asia is developing rapidly, and downstream industries such as automobiles, electronics, and engineering machinery have a strong demand for metallurgical casting products. The exhibition provides a direct channel for enterprises to reach local buyers and end customers;

2. Technology docking platform: Bringing together globally leading equipment and technology solutions to help enterprises understand industry innovation directions, achieve technological upgrades and product iterations;

3. International Cooperation Bridge: Attract exhibitors and visitors from multiple countries to participate, promote cross regional integration of industrial chain resources, and provide important opportunities for Chinese enterprises to "go global" in Southeast Asia.

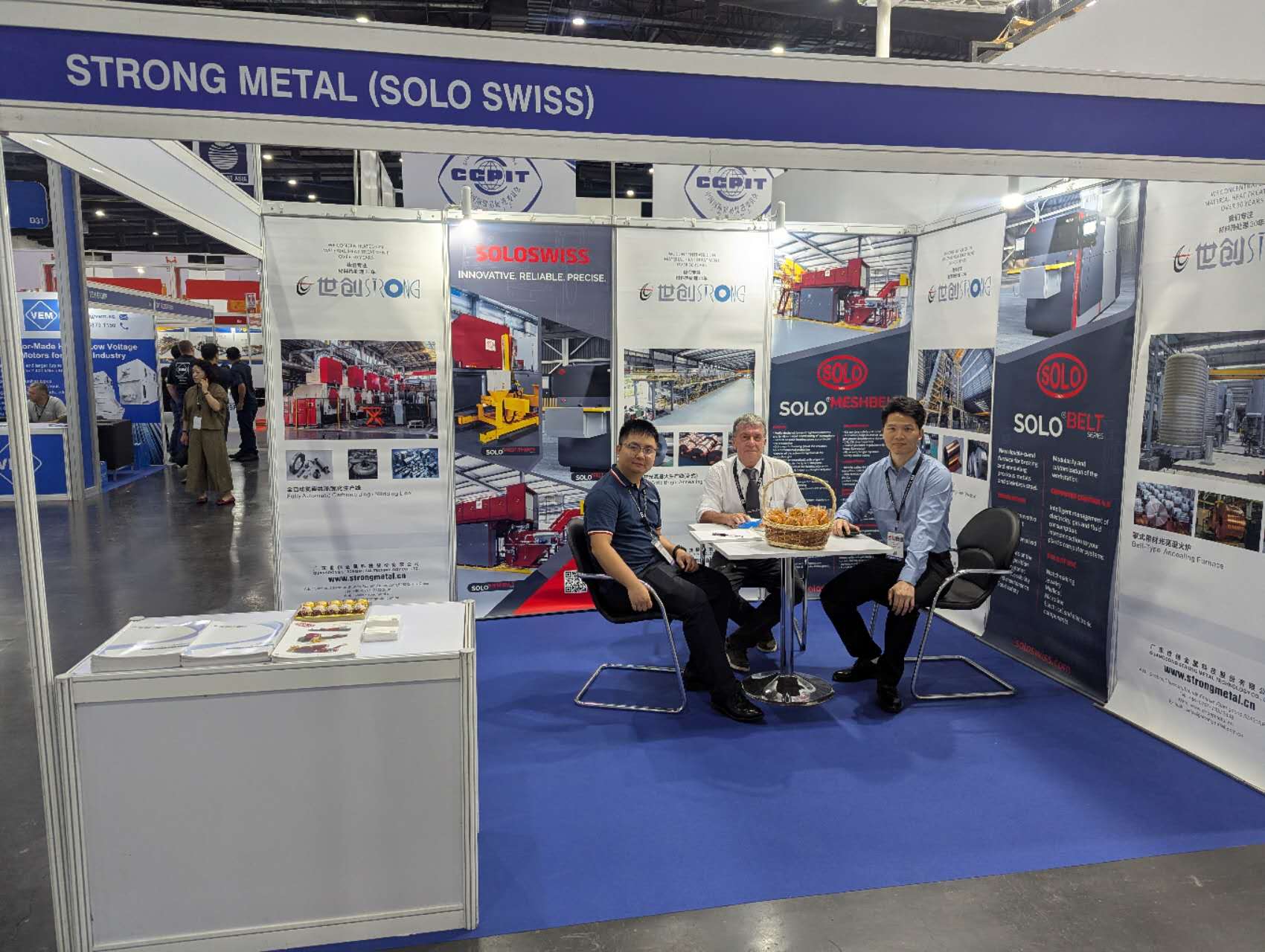

E.Strong Metal And Solo

For this exhibition, we are honored to invite our business partner Solo Chairman Jean Michel Laomi, who is working together with us, to continue writing a new chapter of cooperation between Guangdong Strong Metal Materials Co., Ltd. and Solo, and pave the way for the heat treatment industry to enter overseas markets

Service Hotline | +8615820281234

E-mail | mac@strongmetal.com.cn

Website | www.strong-furnace.com

Address | No. 32, Shizhou, Chencun, Shunde, Foshan, Guangdong