Chairman of HXF SAW CO., LTD., a leading enterprise in the Chinese sawing industry, and his delegation visited STRONG TECHNOLOGY

On March 17, 2023, Chairman Zhang Yuncai, General Manager, and technicians of HXF SAW CO., LTD., visited STRONG TECHNOLOGY. Chairman Lu Hanming, General Manager Dong Xiaohong, Vice General Manager Wang Guimao, General Manager Liu Xishun, Manager Xie Yingting, and Technical Director Tang Shanjie of Strong Technology warmly received them in the conference room of the company building.

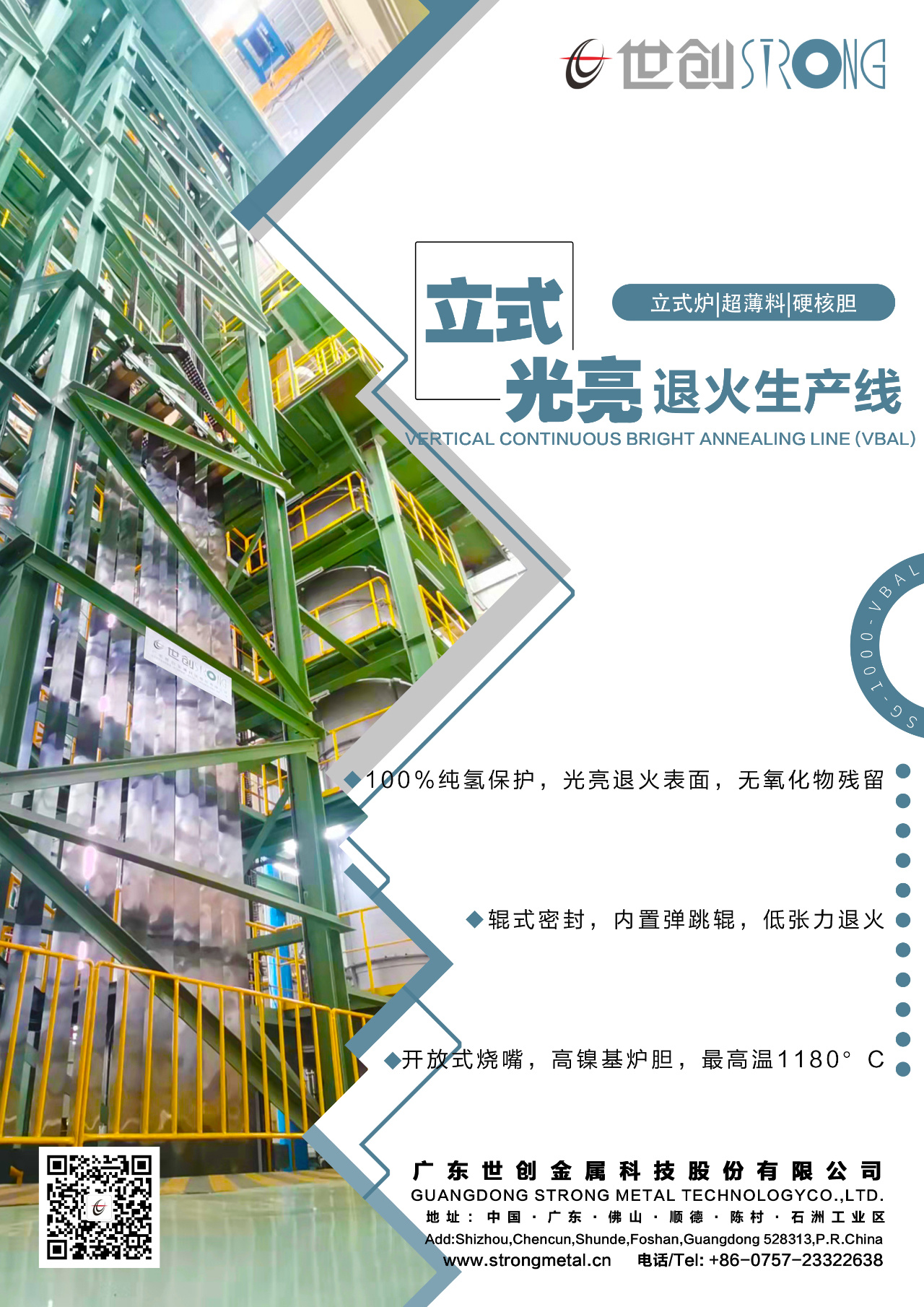

Chairman Zhang of HXF SAW CO., LTD. has further strengthened cooperation with Strong Technology, deeply cultivated the sawing industry, promoted the high-quality development of domestic saw blade substrates, achieved "Specialising in ultra new", improved the quality of existing quenching and tempering lines, and conducted preliminary research on new wide quenching and tempering lines. Liu Xishun, General Manager of the Equipment Department of Strong Technology, is full of confidence in the update of the tempering line. Through years of experience in producing quenching and tempering lines, precision strip bright annealing lines, and alloy strip production lines, combined with technological development, it can fully meet the technical requirements proposed by HXF SAW CO., LTD for equipment.

After the meeting, the Chairman of HXF SAW CO., LTD. and his team went to the Strong Technology Centre to further discuss equipment technology and solve the quality prerequisites that cannot be met at present.

The core technology of this production line lies in accurately controlling the temperature, time, speed and other process parameters of each stage based on the process curve. The various technical parameters of the quenching unit are particularly important to meet the requirements of graded quenching. The product requires quenching and tempering structure (performance) to meet the requirements, surface brightness, good flatness (up to 1/1000), high yield ratio, and small hardness deviation.

A continuous annealing furnace line is a type of industrial furnace that is used to heat and cool metal strips in a continuous process. The furnace line typically consists of a series of chambers, each of which is heated to a different temperature. The metal strip is passed through the chambers in a conveyor belt, and the temperature of the strip is gradually increased as it passes through the line.

The purpose of annealing is to soften the metal and make it more ductile. This is done by heating the metal to a temperature above its recrystallization temperature, and then cooling it slowly. The recrystallization temperature is the temperature at which the metal's crystal structure changes from a distorted form to a more regular form.

Continuous annealing furnace lines are used in a variety of industries, including the steel, aluminum, and copper industries. They are used to produce a variety of metal products, including sheet metal, wire, and tubing.

Here are some of the benefits of using a continuous annealing furnace line:

It is a more efficient way to heat and cool metal strips than traditional batch annealing methods.

It produces a more uniform product with better quality control.

It can be used to produce a wider variety of metal products.

Here are some of the challenges of using a continuous annealing furnace line:

The furnace line is a complex piece of equipment, and it requires careful maintenance.

The metal strip must be precisely controlled in order to ensure that it is heated and cooled evenly.

The furnace line can be a fire hazard, and it must be carefully operated.

Service Hotline | 0757-2332 2638

Website | www.strongmetal.cn

Address | No. 32, Shizhou, Chencun, Shunde, Foshan, Guangdong