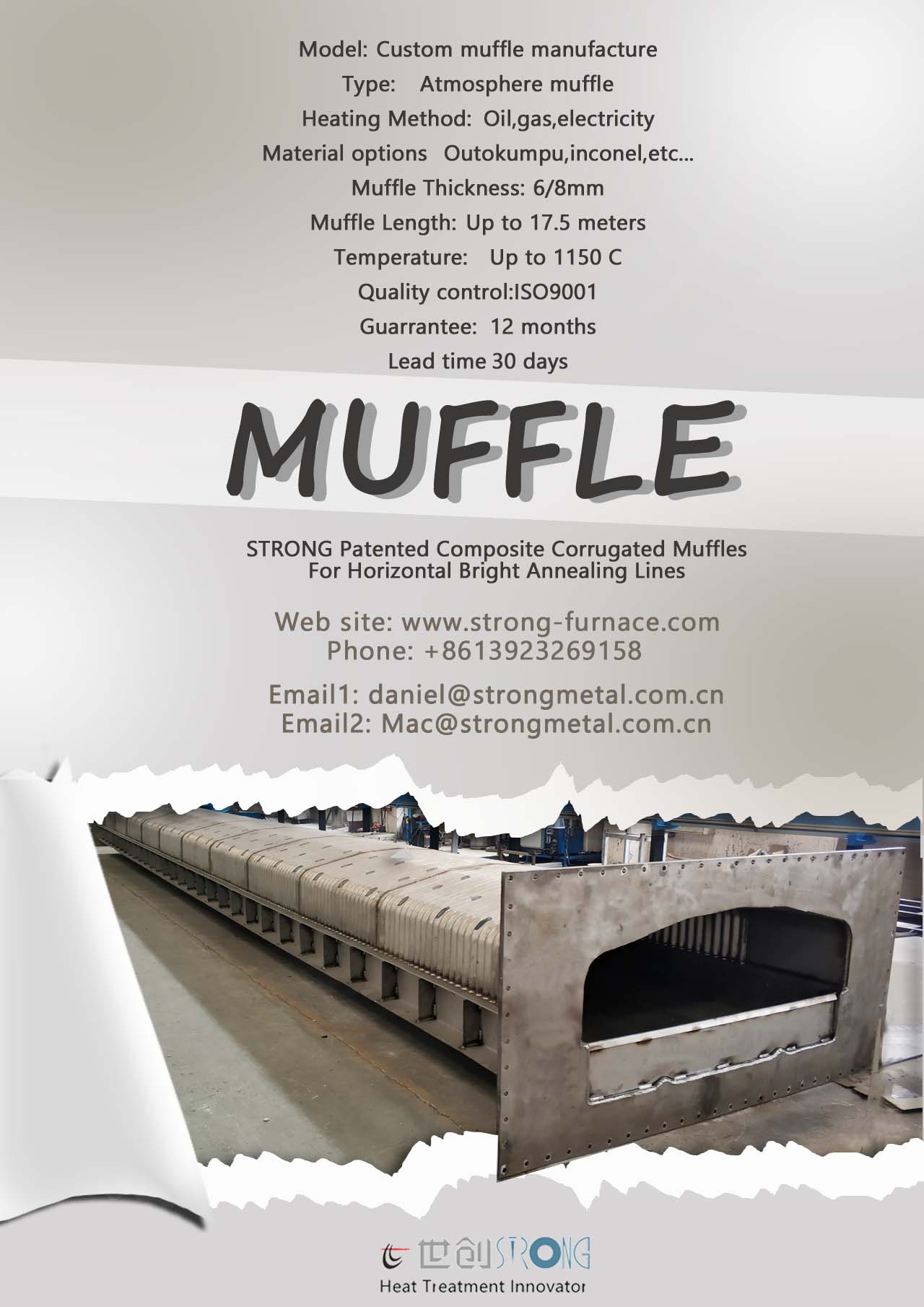

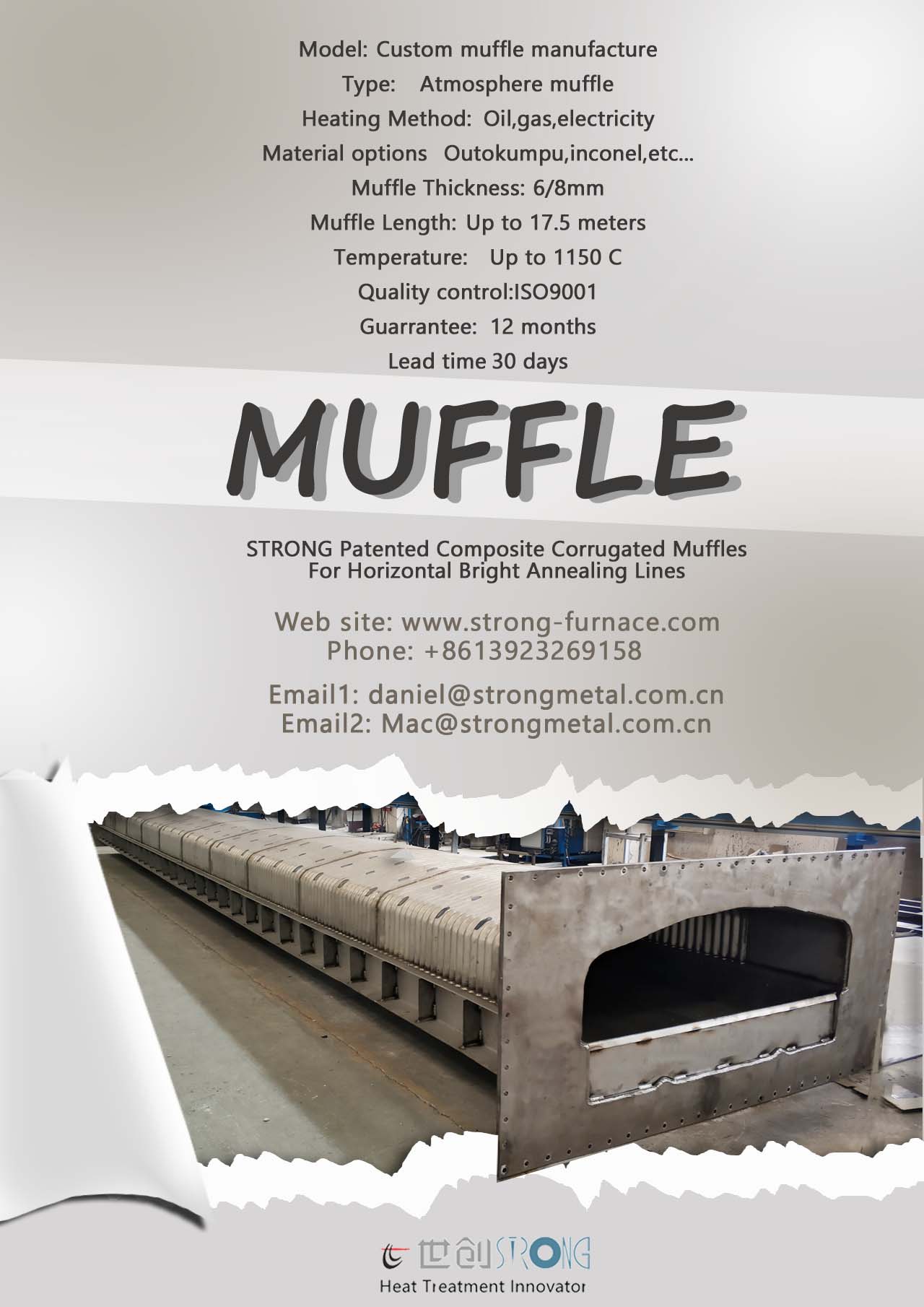

- Muffles for Furnaces

- Muffles For Horizontal Furnaces

- Muffles For Vertical Furnaces

- Muffles For Bell Furnaces

- Muffles For Carburizing Nitriding

- Muffles for conveyor furnaces

- Muffles For Ammonia Crackers

STRONG Technology new patent information authorization: "A metal strip transmission system with vertical nested looping structure

“New third Board innovation layer company Strong Technology (833136) new patent information, the patentee is Shichuang Technology, the inventors are Wang Guimao, Liang Zheng, Liu Xishun, Li Sen. The patent authorization date is March 7, 2023, the patent name is "a metal strip transmission system with vertical nested loop structure", the patent type is China utility model patent, and the patent application number is CN202221793838.7.”

The patent abstract shows:

New third Board innovation layer company Shichuang Technology (833136) new patent information, the patentee is Shichuang Technology, the inventors are Wang Guimao, Liang Zheng, Li Shucheng, Li Weida. The patent authorization date is May 27, 2022, the patent name is "a steering structure for molten metal quenching", the patent type is China utility model patent, and the patent application number is CN202122741656.7.

The utility model relates to a steering structure for molten metal quenching, which is arranged at the entrance of a molten metal quenching pool, and is characterized in that the structure comprises a box, a rotating shaft mechanism and a lifting mechanism, a rotating shaft mechanism is arranged with a rotating shaft, the main body of the rotating shaft is connected with a drum and is located in the inner cavity of the box, and the end of the rotating shaft is located outside the box and connected with a rotating drive structure; The wear-resistant cloth is rolled in the drum, and the wear-resistant cloth is rolled on the drum to form an extendable roll structure, so as to facilitate the rotation of the wear-resistant cloth at the steering part by driving the rotating shaft; The lifting mechanism is connected to the bottom surface of the rotating shaft mechanism to form the driving structure of the rotating shaft mechanism to rise or fall. It has the characteristics and progress of not requiring frequent replacement of wear-resistant materials, maintaining continuous work of the production line, ensuring stable product quality, maintaining stable furnace atmosphere and low production costs.

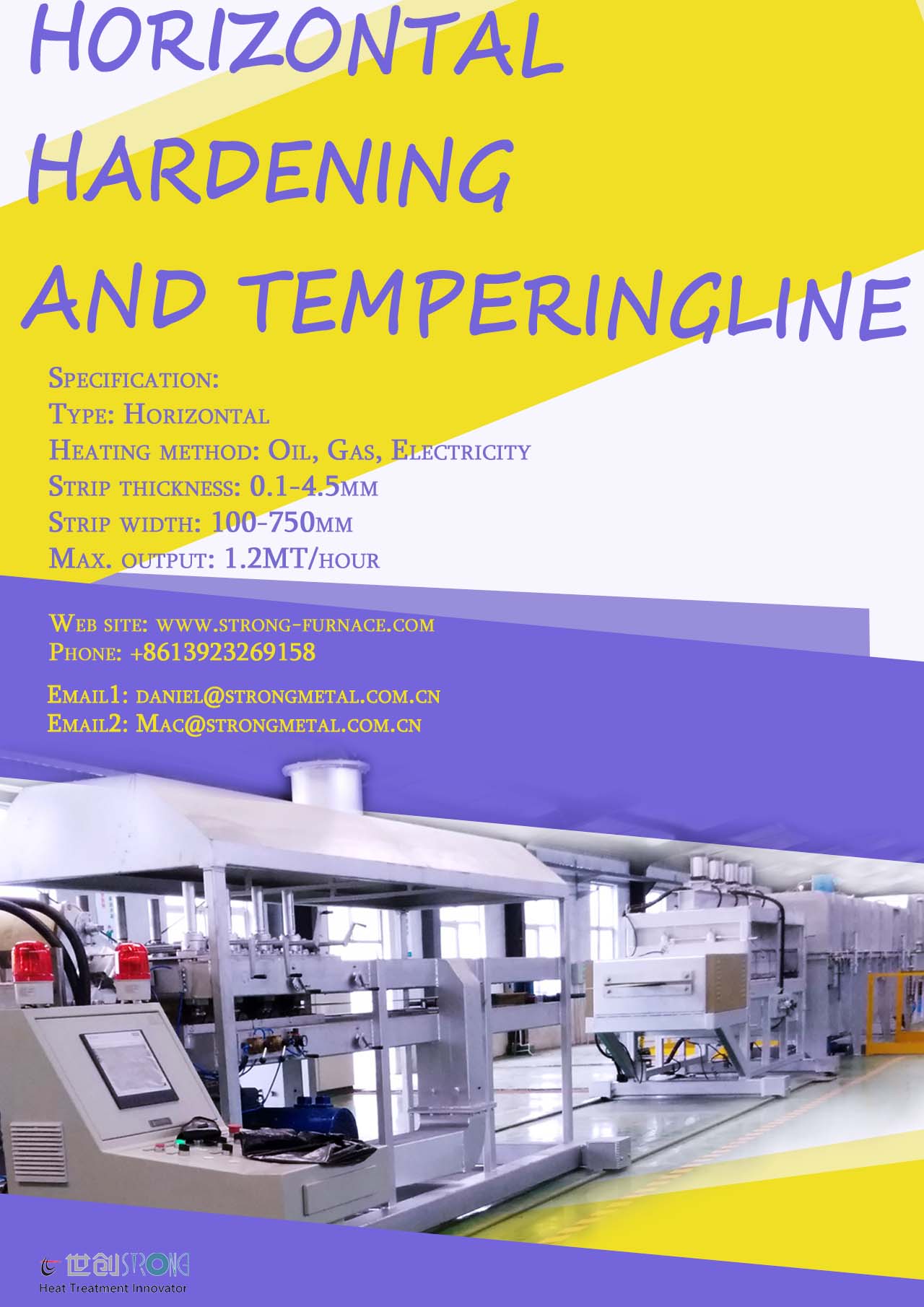

Hardening and tempering lines are used to heat treat metal parts in a continuous process.

The process involves heating the metal to a high temperature, quenching it to rapidly cool it, and then tempering it to relieve stress and improve the properties of the metal.

Hardening and tempering lines are used to produce a variety of metal parts, including gears, shafts, and springs.

They are used in a wide range of industries, including the automotive, aerospace, and manufacturing industries.

The key components of a hardening and tempering line include:

A heating furnace: This furnace is used to heat the metal to a high temperature.