China iot Steel Logistics Professional Committee: Steel market demand is expected to expand in August

Every AI news, according to the official micro of the steel logistics Professional

Committee of the China iot, it is expected that the steel market demand will

expand in August.

First, policies promoted the release of relevant demand.

At the end of July, the Political Bureau meeting stressed that it is necessary to

promote the stable and healthy development of the real estate market, promote

the transformation of urban villages and the construction of "dual use" public

infrastructure, vigorously promote the construction of the modern industrial

system, actively expand domestic demand, and boost the bulk consumption of

automobiles, electronic products, home appliances, etc., which is a series of

information that benefits steel demand in many ways.

The second is the natural steady recovery of steel demand.

In early August, all places are still in high temperature and rainy weather, steel

market demand has been suppressed in the short term, but with the end of the

rainy season, coupled with the arrival of the "gold nine silver ten" peak season,

steel demand will gradually enter the recovery channel.

The expected index of production and operation activities was 59.5%, up 2.7

percentage points from the previous month, and the quarter picked up for four

consecutive months, indicating that enterprises are more optimistic about the

future market expectations.

(National Business Daily)

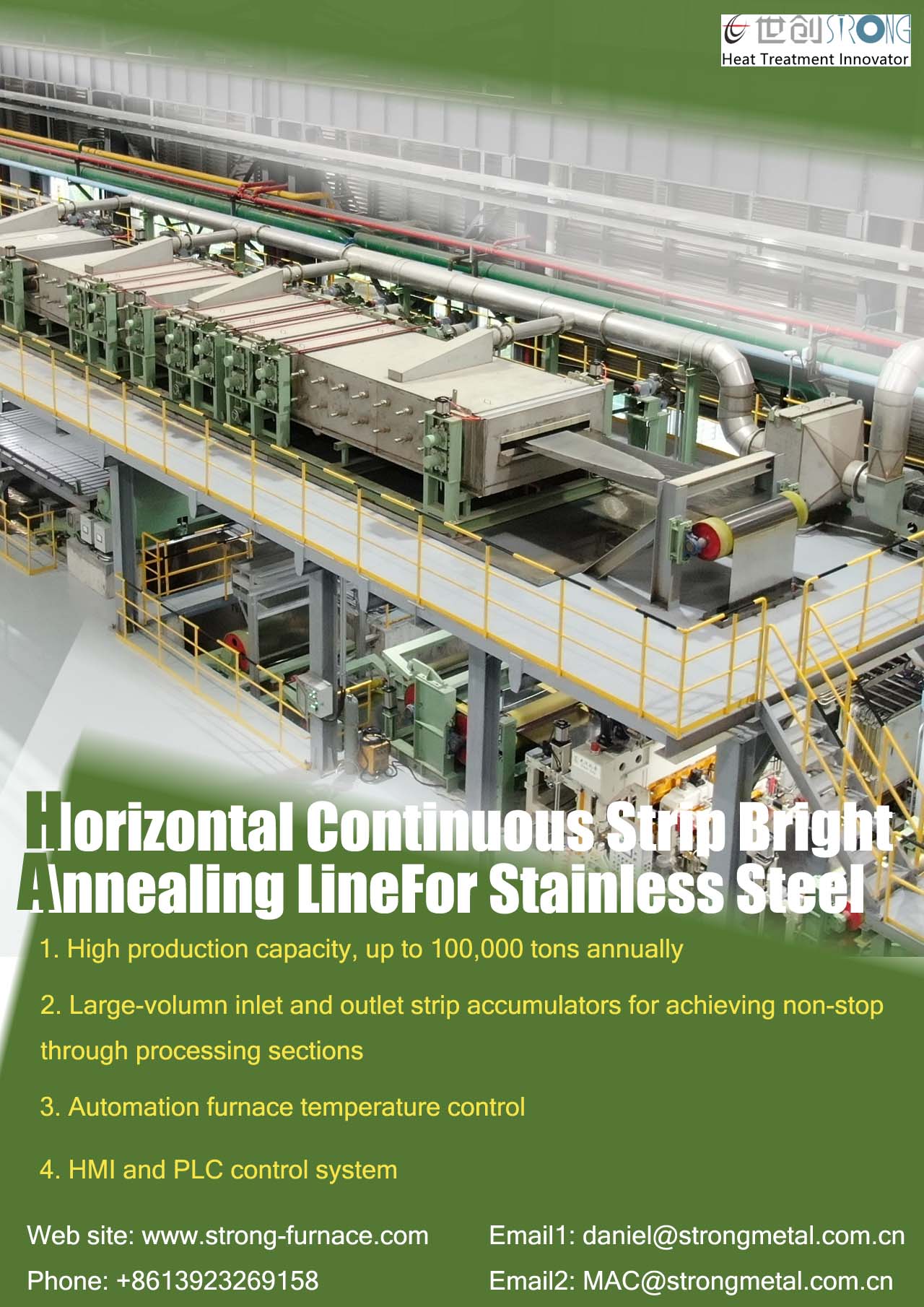

Bright annealing lines are used to heat and anneal metal strips in a controlled atmosphere. The annealing process produces high-quality metal strips with a smooth, bright finish. It also improves the mechanical properties of the metal strips.

Bright annealing lines typically consist of the following components:

Uncoiler: This unit unwinds the metal strip from a coil.

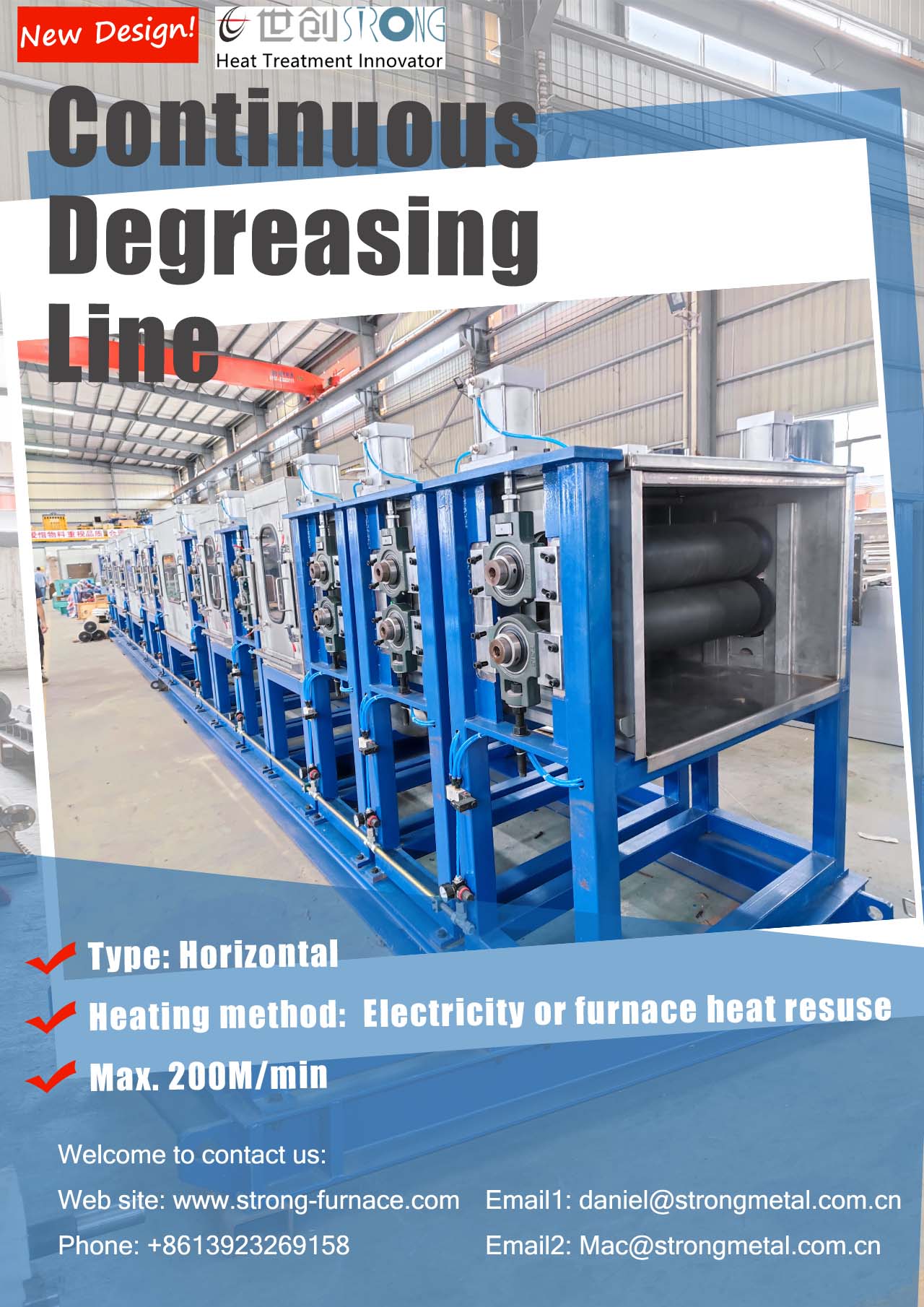

Degreasing unit: This unit removes any dirt or oil from the metal strip.

Rollers: These rollers transport the metal strip through the furnace.

Muffle furnace: This furnace is where the metal strip is heated and annealed.

Loopers: These loopers keep the metal strip in a continuous loop as it passes through the furnace.

Winder unit: This unit winds the metal strip back into a coil.

The annealing process in a bright annealing line typically takes place in two stages:

The metal strip is heated to a temperature between 700 and 900 degrees Celsius.

The metal strip is held at this temperature for a period of time, typically between 10 and 30 minutes.

The annealing process causes the metal strip to recrystallize, which improves its mechanical properties. It also removes any residual stresses in the metal strip, which can cause it to warp or bend.

The controlled atmosphere in a bright annealing line is typically inert gas, such as argon or helium. This prevents the formation of surface oxide on the metal strip, which would give it a dull finish.

Bright annealing lines are used to produce a variety of metal strips, including stainless steel, aluminum, and copper. They are used in a wide range of industries, including the automotive, aerospace, and medical industries.

The benefits of using bright annealing lines include:

High production rate: Bright annealing lines can produce a large number of metal strips in a short amount of time.

Improved quality: The annealing process produces high-quality metal strips with a smooth, bright finish.

Reduced costs: Bright annealing lines can help to reduce the cost of producing metal strips.

The disadvantages of using bright annealing lines include:

High initial investment: Bright annealing lines are a significant investment.

Complex operation: Bright annealing lines are complex to operate and maintain.

Specific requirements: Bright annealing lines require specific materials and conditions to operate effectively.