- Muffles for Furnaces

- Muffles For Horizontal Furnaces

- Muffles For Vertical Furnaces

- Muffles For Bell Furnaces

- Muffles For Carburizing Nitriding

- Muffles for conveyor furnaces

- Muffles For Ammonia Crackers

China Iron and Steel Association: expected in the second half of the year steel exports or pressure fall imports continue to remain low

According to the China Iron and Steel Industry Association on July 27 news,

in the first half of the year, China's steel import and export market showed

a significant increase in exports and a sharp decline in imports,

of which the export end showed a large increase in exports of most varieties

and most regions, and the import end showed a large decline

in imports of most varieties and major regions.

上证报中国证券网讯 据中国钢铁工业协会7月27日消息,上半年,我国钢材进出口市

场呈现出口明显增加进口大幅下滑趋势,其中出口端呈现出多数品种、多数区域出口

大幅增长的局面,进口端呈现出多数品种、主要区域进口大幅下滑的局面,

The characteristics of the import and export market are closely related to the

phased development of the steel market at home and abroad.

进出口市场呈现出的特点与国内外钢材市场阶段性发展密切相关。

Looking forward to the second half of the year, due to the weakening of overseas

steel demand, exchange rate fluctuations and other factors, it is expected that

steel exports or pressure fall, imports continue to remain low.

展望下半年,由于受海外钢材需求走弱、汇率波动等因素影响,预计钢材出口或承压回落,

进口继续保持低位。

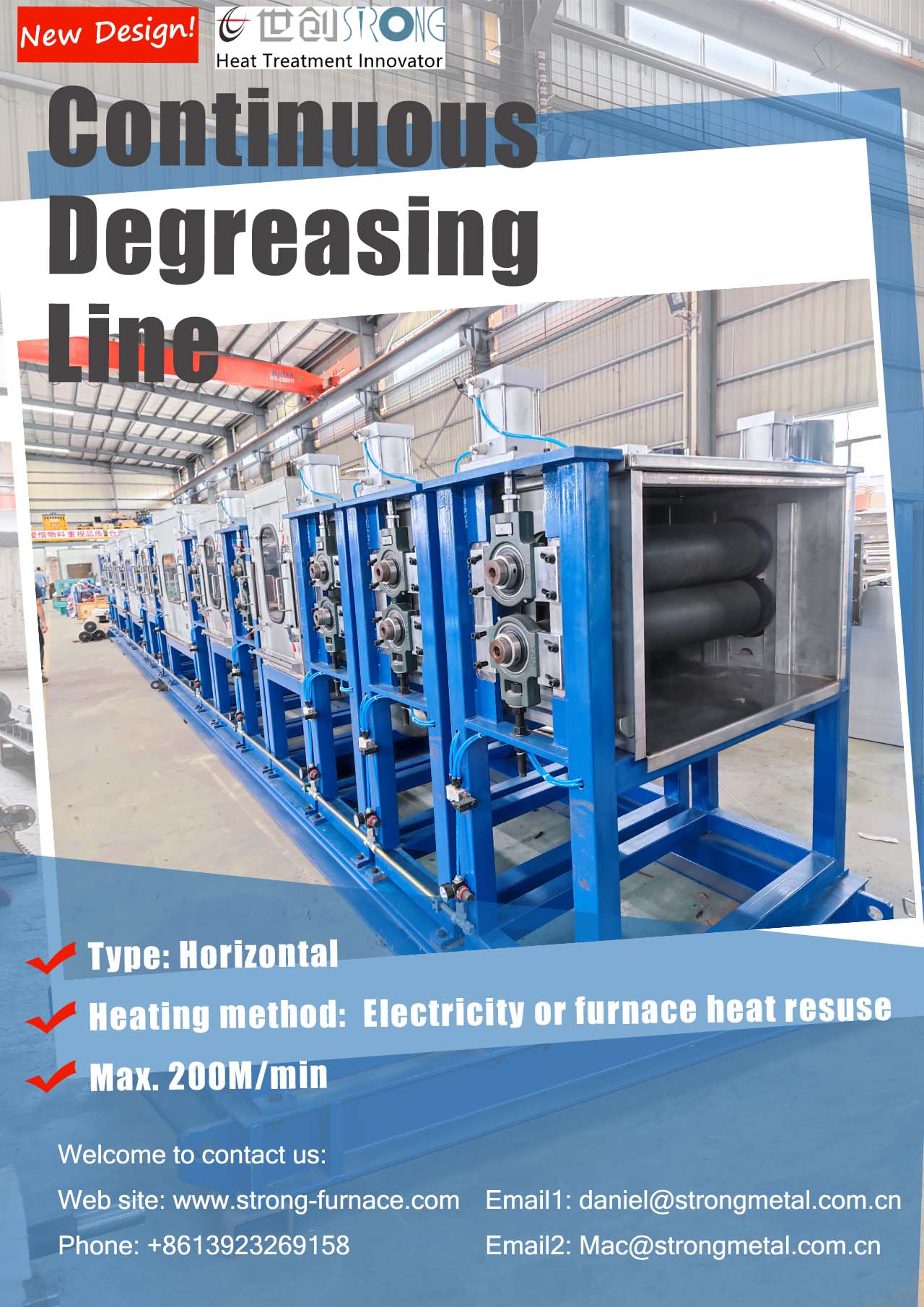

“Degreasing lines are used to remove oil, grease, and other contaminants from metal parts. They are typically used in the metalworking industry, but they can also be used in other industries, such as the automotive and aerospace industries.

Degreasing lines typically consist of the following components:

A conveyor system: This system is used to transport the metal parts through the line.

A pre-wash station: This station is used to remove loose dirt and debris from the metal parts.

A degreasing tank: This tank is filled with a degreasing solution, such as an alkaline or solvent-based solution.

A rinse station: This station is used to rinse the metal parts with water.

A drying station: This station is used to dry the metal parts.

The degreasing process typically takes place in two stages:

The metal parts are immersed in the degreasing tank. The degreasing solution dissolves the oil, grease, and other contaminants on the metal parts.

The metal parts are rinsed with water to remove the degreasing solution.

The benefits of using degreasing lines include:

Improved cleanliness: Degreasing lines can remove oil, grease, and other contaminants from metal parts, which improves their cleanliness.

Reduced corrosion: Degreasing lines can help to reduce corrosion by removing oil and grease, which can attract moisture.

Improved surface finish: Degreasing lines can improve the surface finish of metal parts by removing contaminants that can cause the surface to be dull or rough.

The disadvantages of using degreasing lines include:

High initial investment: Degreasing lines are a significant investment.

Complex operation: Degreasing lines are complex to operate and maintain.

Specific requirements: Degreasing lines require specific materials and conditions to operate effectively.

Here are some of the different types of degreasing lines:

Alkaline degreasing lines: These lines use alkaline solutions to remove oil, grease, and other contaminants from metal parts.

Solvent degreasing lines: These lines use solvents to remove oil, grease, and other contaminants from metal parts.

Ultrasonic degreasing lines: These lines use ultrasonic waves to remove oil, grease, and other contaminants from metal parts.

The type of degreasing line that is used will depend on the specific requirements of the application. For example, alkaline degreasing lines are typically used for removing oil and grease from metal parts that will be painted, while solvent degreasing lines are typically used for removing oil and grease from metal parts that will be used in electrical applications.